Modern Aluminum Windows and Doors

"The Future of Architecture: Modern Aluminum Windows and Doors"

Aluminum Windows, although not as popular in Poland until recently, are now conquering the market of joinery. Aluminum windows are known for their exceptional durability. With technological and design advancements, aluminum joinery has become even more attractive to customers who seek not only durable and energy-efficient solutions but also aesthetic design. In this article, we present five key advantages of modern aluminum joinery and address the question of whether aluminum solutions are energy-efficient.

Aluminum windows are characterized by high resistance to weather conditions.

One of the most significant advantages of aluminum joinery is its exceptional resistance to weather conditions. Aluminum windows are resistant to rain, snow, wind, and UV radiation. Aluminum products can be particularly protected against corrosion by strengthening the oxide layer through processes like anodizing or surface treatment, such as painting. Thanks to the fact that aluminum does not deform or delaminate, these windows maintain their shape and functionality for many years.

The possibility of creating non-standard shapes of aluminum windows.

Another advantage of aluminum joinery is the possibility to create non-standard window shapes, for example, the extremely popular large triangular windows in recent times. During the aluminum production process, aluminum is a flexible material that can be easily molded and processed. This allows manufacturers to have great freedom in designing various shapes that can be tailored to individual architectural requirements. Whether it's windows with non-standard dimensions, arches, or angles, aluminum joinery enables the implementation of unconventional solutions.

Glass walls, thanks to aluminum joinery

Aluminum joinery is also distinguished by its high rigidity, which enables the creation of large glazed areas. Thanks to its exceptional strength, aluminum frames can accommodate large glass panes, allowing the creation of glass walls. Large glazing creates a sense of spaciousness, opens interiors to the outside, and improves the comfort of using the rooms. Undoubtedly, this is one of the leading trends in construction in recent years. Additionally, aluminum window profiles allow for the use of thinner frames, further increasing the field of view and enhancing aesthetics.

Unique design

The last, but not least important advantage of aluminum joinery is its attractive design. Aluminum allows for the creation of sleek, modern window frames that perfectly fit architectural trends. Various color options are available (achieved through anodizing or powder coating, allowing for almost any shade from the RAL palette). There is also the option to apply wood imitating effects. As a result, aluminum windows serve not only as functional solutions but also as decorative elements that enhance the aesthetics of the entire building.

Is aluminum joinery energy-efficient?

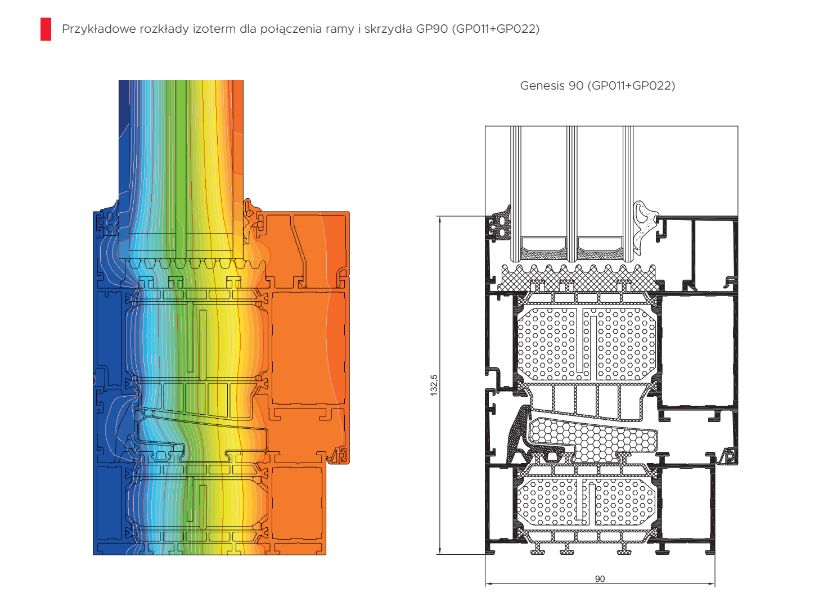

Until recently, people not associated with the joinery industry and lacking technical knowledge might have perceived aluminum windows as cold windows that do not provide sufficient protection against room cooling. However, today's aluminum windows are on par with windows made from other materials. Thanks to the use of appropriate thermal insulators in aluminum profiles, such as thermal breaks made of polyamide, excellent thermal insulation is ensured throughout the entire service life of the joinery. Thermal breaks made of polyamide reinforced with fiberglass not only increase the stiffness of the profiles but also effectively protect against heat loss, regardless of weather conditions. The distribution of isotherms is also crucial, and in aluminum windows, it is practically linear, preventing cold from penetrating inside.

In combination with suitable glazing units, such as low-emissivity glass, aluminum windows can effectively meet the requirements of highly energy-efficient buildings, including passive houses and energy-efficient homes. Thanks to continuous improvement in production technology and ongoing research to enhance thermal insulation, the aluminum window industry is evolving rapidly. Already now, they achieve highly favorable heat transfer coefficients for the entire window Uw = 0.8 - 1.1 W/(m2.K), and the most thermally efficient even record-low 0.53 W/(m2.K). These values are provided for a reference window with dimensions of 123 x 148 cm.

In practice, this means that aluminum windows can be energy-efficient, especially when equipped with appropriate insulation solutions and glazing units. This ensures effective protection against heat loss, resulting in reduced energy consumption required for heating the rooms.

Polski

Polski English

English Germany

Germany France

France