Types and parameters of glazing

Selecting windows for your home is a stage that can make the client really dizzy. One of the key elements that affect the window parameters are, of course, glass panes, which cover about 70% of the area of a traditional window, and even more in case of large terrace glazing.

When receiving an offer, very often we come across technical records, e.g. a 3-pane package or markings e.g. 4/16/4/16/4, which say little to a person not associated with the window industry on a daily basis. In this article we will try to explain on glazing and decipher the most important parameters in order to facilitate reliable comparison of offers and final selection.

What are insulated glazing units?

A glazing unit is a structure consisting of at least two panes that form an inter-pane chamber containing air or other gases, separated from each other and sealed around its entire circumference by a spacer, sealants and vapour-absorbing substances.

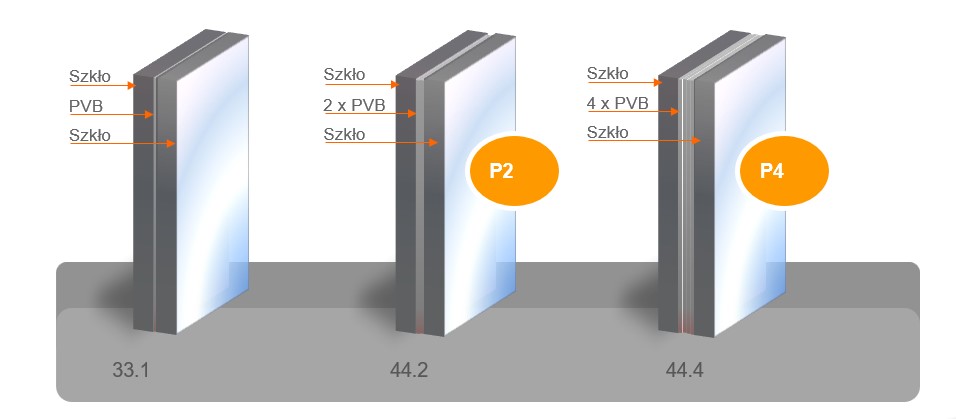

Manufacturers offer single-chamber glazing consisting of two panes of glass and two- and three-chamber glazing consisting of three and four panes of glass (in case of safety glazing and larger number of panes bonded by PVB foil).

Double-glazing material is float glass, which features high light permeability and a perfectly flat surface frequently covered with special coatings. This makes that the multi-layer structure of a pane does not limit visibility.

Modern solutions make the double glazing units effectively protecting against loss of heat, excessive heating or noise and provide temporary protection against burglary.

Insulated glazing units and their parameters ?

| Section | Description |

|---|---|

Symbol 4/16/4 |

Single-chamber insulated glazing unit 4mm thick outer pane / 16mm wide spacer / 4mm thick inner pane. Inter-pane space filled with air. Total thickness of glazing unit = 4 + 16 + 4 = 24 mm |

Symbol 33.1/16/4 |

Layered single-chamber insulated glazing unit The layered outer pane is made of two 3mm thick glass panes combined with one layer of 0.38mm thick PVB film / 16mm wide spacer frame / 4mm thick inner pane. Inter-pane space filled with air. Total thickness of glazing unit = 6,4 + 16 + 4 = 26,4 mm *thickness of PVB film is noted approximately as 0.4mm for calculation purposes. |

Examples of two-chamber glazing unit packages

| Section | Description |

|---|---|

Symbol 4/16/4/16/4 |

Double-chamber insulated glazing unit 4mm thick outer pane / 16mm wide spacer / 4mm thick middle pane / 16mm wide spacer / 4mm thick inner pane. Inter-pane space filled with air. Total thickness of glazing unit = 4 + 16 + 4 + 16 + 4 = 44 mm |

Symbol 44.2/16/4/16/4 |

Layered double-chamber insulated glazing unit Layered outer glass made of two 4mm thick panes combined with two layers of 0.38mm thick PVB film / 16mm wide spacer / 4mm wide middle pane / 16mm wide spacer / 4mm thick inner pane. Inter-pane space filled with air. Total thickness of glazing unit = 8,8 + 16 + 4 + 16 + 4 = 48,8 mm |

Examples of three-chamber gas-filled insulated glazing packages

| Section | Description |

|---|---|

Symbol 3/14Kr/3/14Kr/3/14Kr/3 |

Triple-chamber insulated glazing unit 3mm thick outer pane / 14mm wide distance frame / 3mm thick first middle pane / 14mm wide distance frame / 3mm thick first middle pane / 14mm wide distance frame / 3mm thick inner pane. All inter-pane spaces are filled with a mixture of Krypton (Kr) and air. Total thickness of glazing unit = 3 + 14 + 3 + 14 + 3 + 14 + 3 = 54 mm |

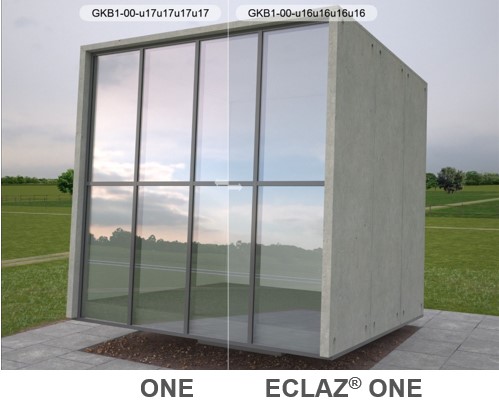

Thermal insulated glazing units

Thermal insulation glazing is a unit that contains additional elements such as noble gas between the chambers or special coatings on the panes, which are designed to reduce heat loss and save energy. The most important parameter which determines thermal insulation properties of panes is the coefficient of thermal transmittance U, which characterises the amount of thermal energy that penetrates through a pane. The lower the U-value, the better the thermal insulation properties. As a rule, each successive chamber improves the above mentioned parameter, however, adding another pane also reduces level of light penetration in the room (Lg) as well as thermal energy (g) that the sun rays convey. In some cases, level of light reflection (Rlex or Lr) is also important, e.g. in case of glazing units for shop windows or car showrooms, it should be as low as possible so that the façade does not form a mirror effect..

Basic parameters of glazing units:

Ug – W/m2K – heat transfer coefficient. It is an amount of heat that permeates - in a unit of time - through 1m2 of the partition wall with 1 Kelvin temperature difference on both sides of the partition. The value of Ug coefficient according to EN 673 is calculated for the central part of the pane. In practice, the coefficient indicates how much heat is escaping from our house / insulation of the glass.

The lower the Ug value, the better.

Light transmittance - Tl (%) or Lg (%) - is the percentage of visible light that comes from the sunlight and passes through the glass.

Solar factor - g (%) is the coefficient of total solar energy transmittance; this is the sum of energy passing directly through the glass and energy radiated through the glass as a result of its heating. In other words, this is the amount of heat that passes through glass to our home (in winter - the more the better).

Light reflection - Rlex (%) or Lr (%) - is the percentage of visible light, coming from the sun and reflected through the glass. In practice it indicates brightness of the glass.

How to read parameters for heat-insulated glazing units?

|

Description/symbol of a double-glazing unit construction |

Lt (%) |

Rlex (%) |

g (%) |

Ug ≤ W/(m2*K) |

|

4/16Ar/ ECLAZ 4 1,1 |

83 |

12 |

71 |

1,1 |

|

Thermo-insulating single-chamber glass unit with ECLAZ coating 4mm thick outer pane / 16mm wide spacer / 4mm thick inner pane with ECLAZ coating. Inter-pane space filled with a mixture of Argon and air. The package features thermal transmittance coefficient Ug=1.1 W/(m2*K). The light transmission coefficient Lt = 83%. The total energy transmittance of solar radiation g = 70% and the light reflectance is Rlex(%) 12%. Total thickness of glazing unit = 4 + 16 + 4 = 24 mm |

||||

|

4 ECLAZ/16Ar/4/16Ar/ECLAZ 4 0,6 |

77 |

14 |

60 |

0,6 |

|

Thermo-insulating double-chamber glass unit 4mm thick outer pane with ECLAZ coating / 16mm wide spacer / 4mm wide middle pane / 16mm wide spacer / 4mm thick inner pane with ECLAZ coating. Inter-pane space filled with a mixture of Argon and air. The package features thermal transmittance coefficient Ug=0,6 W/(m2*K). The light transmission coefficient Lt = 77%. The total energy transmittance of solar radiation g = 60% and the light reflectance is Rlex(%) 14%. Total thickness of glazing unit = 4 + 16 + 4 + 16 + 4 = 44 mm |

||||

Supplementary elements in insulating glass units

Precious gas in the inter-pane spaces - pumped between the panes of insulating glass units separated from each other by a distance frame - performs the function of thermal insulation. Most often it is Argon (Ar) or Krypton (Kr), which, in comparison with air, improves the insulating power of the glass partition by about 30%.

Warm frame is a type of distance frame used in double glazing units. It is usually made of glass fibre-reinforced polymer with additional vapour and gas-tight insulation. It is usually made of glass fibre-reinforced polymer with additional vapour and gas-tight insulation. Its role is to reduce thermal bridge in a location where edges of the double-glazing unit are combined with the frame, thus improving the heat transfer coefficient through the double-glazing unit.

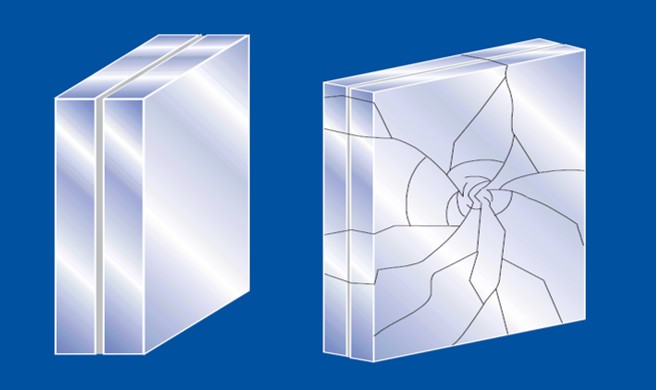

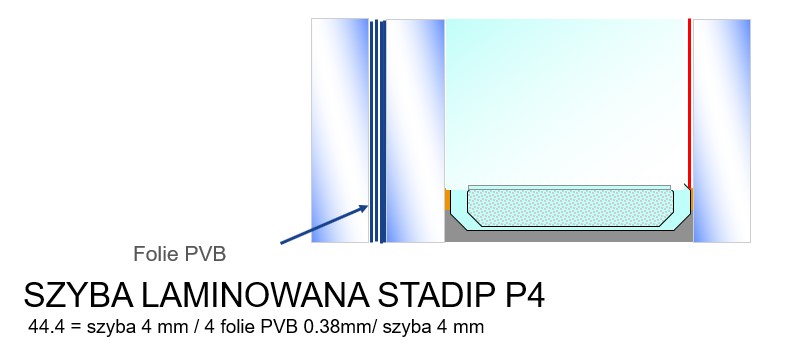

PVB film is the preferred material for production of safety laminated glass. Properties of laminated safety glass that include PVB film result from mechanical properties of this film and very high resistance to tearing of PVB/glass joint in case of glass breakage.

VSG glass is layered laminated safety glass, i.e. composed of two non-tempered panes glued together with a special PVB film. VSG glass most often occurs as anti-burglary, balustrade and protective glass, which in case of puncture or breakage should protect persons in the vicinity from injury as the foil will keep all broken elements in place. This solution is also used in car windscreens.

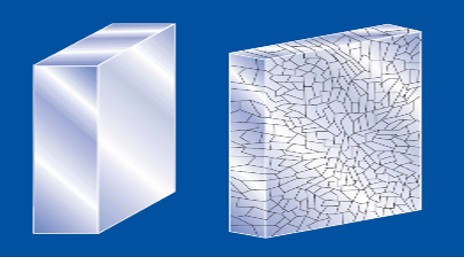

ESG glass (toughened glass) - visually, toughened glass is no different from untreated glass, but the physical characteristics of the glass change. Toughened glass eliminates internal stresses, which in turn provides even 6 times more resistance to breakage. Toughened glass splits into small blurred pieces when broken.

Safety glazing

The statistics show that burglars most often try to get into the building through windows and balcony doors. No wonder that more and more people want to protect their property and stop uninvited guests and choose windows of a higher burglary protection class, e.g. RC2. The difference in strength between these and ordinary windows is very big. In case of this type of glazing, the outer pane is usually the glass panes glued together with the use of several-layer PVB foil.

Examples of single-chamber glazing unit packages

Example:

Anti-burglary glass is generally classified by PN-EN 356 standard. According to the aforementioned standard, anti-burglary glass can be divided into 8 classes: P1A, P2A, P3A, P4A, P5A, P6B, P7B and P8B. These classes differ significantly; to illustrate this we will compare the lowest and the highest classes.

The lowest class, i.e. P1A should withstand three free fall of a 4.11 kg steel ball on the surface of the glass pane mounted in a 1.5 m high frame.

Whereas class P8B dedicated e.g. for high-priced jewellery shops and banks should withstand seventy-fold blows with a hammer and axe weighing 2 kg, with impact energy up to 350J

|

Grade as per EN 356 |

Number of impacts |

Height of drop |

Application |

|

P1A |

3 |

1.5m |

Ground floor windows in blocks of flats, schools, offices, workshops, kiosks, detached houses, hotel and office windows, sports halls, commercial buildings, pharmacies |

|

P2A |

3 |

3.0m |

|

|

P4A |

3 |

9.0m |

Houses, showcases in lounges, hotels and offices, villas, high protected value commercial buildings |

|

P5A |

9 |

9.0m |

Museums, antique shops, art galleries, psychiatric institutions, bank operation halls, currency exchange shops, shops of high protected value, exclusive villas |

|

The test is carried out by single or multiple impacts of a 4.11 kg steel ball falling freely from a specific height |

|||

How to read parameters for safety glazing units?

Description of a double-glazing unit construction: 33.1/16Ar/4

Single-chamber safety glass unit

Layered outer pane made of two 3mm thick glass panes combined with one layer of 0.38mm thick PVB film / 16mm wide spacer / 4mm thick inner pane. The inter-pane space is filled with a mixture of Argon and air.

Total thickness of glazing unit = 6,4 + 16 + 4 = 26,4mm

Description of a double-glazing unit construction: 44.4/16Ar/4/16Ar/44.4 P4A

Double-chamber insulating glass unit in burglary resistance class P4A according to PN-EN 356:2000 standard.

Layered outer pane made of two 4mm thick glass panes, combined with four layers of 0.38mm thick PVB film / 16mm wide spacer / 4mm wide monolithic center pane / 16mm wide spacer / 16mm wide spacer / Layered inner pane made of two 4mm thick glass panes combined with four layers of 0.38mm thick PVB film. The inter-pane space is filled with a mixture of Argon and air.

Total thickness of glazing unit = 9,6 + 16 + 4 + 16 + 9,6 = 55,2mm

Soundproofing glasses

Noise protection is one of the most important aspects that affect the comfort of living. Large vehicle traffic, dense buildings, the proximity of industrial plants, playgrounds and sports fields make noise very troublesome.

An effective solution is the use of sound-absorbing glasses, which, due to their structure, will provide adequate sound insulation. The use of such glazing significantly affects acoustic properties of the window, its ability to dampen noise, and thus affects comfort of the residents.

Sound-absorbing glass is a composite glass that combines high thermal insulation parameters with very good sound insulation. Acoustic properties of double-glazed units are measured by the weighted sound insulation index Rw.

The higher Rw the better the sound insulation properties.

source: https://pl.saint-gobain-building-glass.com/pl/Sz%C5%82o-o-w%C5%82a%C5%9Bciwo%C5%9Bciach-izolacji-akustycznej

How to read parameters soundproofing glasses?

Two-chamber soundproofing glasses

Example:

|

Description of a double-glazing unit construction |

Rw |

C |

Ctr |

RA1 |

RA2 |

|

VSG 33.1T/12/4/12/VSG 33.1T |

37 |

-3 |

-8 |

34 |

29 |

|

Two-chamber insulated soundproof glass unit Layered outer pane made of 3mm thick two glass panes combined with one layer of 0.38mm thick PVB film / 12mm wide distance frame / 4mm thick inner pane / 12mm distance frame / Layered inner pane made of 3mm thick two glass panes combined with one layer of 0.38mm thick PVB film. The inter-pane space is filled with a mixture of Argon and air. Ważony współczynnik izolacyjności akustycznej właściwej = Rw 37(-3;-8) dB. Współczynnik izolacyjności akustycznej właściwej RA1 = 34 dB. Współczynnik izolacyjności akustycznej właściwej RA2 = 29 dB. |

|||||

Polski

Polski English

English Germany

Germany France

France