How to read quotes from window suppliers and what does each piece of information mean?

Windows are one of the most important elements of a house. They provide natural light in interiors, affect the visual effect, the comfort of occupants and also the amount of heating bills. Choosing the right windows is no doubt not an easy task. Colour or visual considerations are just the tip of the iceberg. Attention should be paid to technical specifications. It's easy to get confused here, markings such asUw, RwLt or RC2 can be problematic to decipher, so we've come up with a short guide to window parameters.

U – thermal transmittance value

The thermal transmittance value is one of the most important parameters to be calculated and controlled during the construction of a house. Poorly constructed thermal insulation can cause up to 30% heat loss. And with that comes higher energy consumption, environmental pollution and higher heating bills.

The U-value describes the ability of a building envelope to transmit heat. It determines how much energy (expressed in watts) passes through 1 square metre of partition (walls, roofs, windows, doors, etc.) when the temperature difference on both sides of the partition is 1 K (Kelvin). The unit of thermal transmittance value is therefore W/(m²-K)

In simpler terms, this value determines the amount of heat that will escape through a particular partition. The smaller the value the better.

Two values are needed to calculate the thermal transmittance U-value: the thermal conductivity λ and the thickness of the partition or material. The formula is as follows: U = λ/d

where: λ - thermal conductivity, d - thickness of partition or material.

The U-value for specific partitions varies.From 2021, new building standards apply, according to which the values are:

- 0.30 W/(m²K) for the floor on the ground,

- 0.20 W/(m²K) for external walls,

- 0.15 W/(m²K) for roofs and flat roofs,

- 0.9 W/(m²K) for windows,

- 1.1 W/(m²K) for roof windows,

- 1,3 W/(m²K) for external doors.

In the case of windows we can distinguish three types of thermal transmittance values: Ug, Uf, Uw

Ug transmittance

Ug is the thermal transmittance value of theglazing, i.e. it characterises the thermal insulation performance of the window pane itself

Windows can be fitted with different types of glazing. Double or triple glazing packages, filling the glazing cavity with noble gas (argon or krypton), pane thickness and the width of the glazing cavity - all this has an impact on the Ug value

Uf transmittance

Uf is the thermal transmittance value of the window frame. The Uf value is determined by measurement or calculation (taking into account, among other things, the profile width) and is usually the highest of the three values Ug, Uf and Uw.

Uw transmittance

Uw is the transmittance of the whole window, so we can say that it is ultimately the most important of these three coefficients. Every manufacturer is obliged to test their windows and communicate to the customer the thermal transmittance values for the windows in a specific model.

Large windows achieve better Uw results compared to smaller glazings because a large glass surface with good thermal insulation achieves a better U value in relation to the frame material.

Weighted sound reduction index Rw

Noise protection is one of the most important aspects that affect the comfort of living. Large vehicle traffic, dense buildings, the proximity of industrial plants, playgrounds and sports fields make noise very troublesome.

An effective solution is the use of sound-absorbing glazing, which, due to their structure, will provide adequate sound insulation. The use of such glazing significantly affects acoustic properties of the window, its ability to dampen noise, and thus affects comfort of the residents.

The sound insulation of windows will be indicated by the Rw index. In contrast to Uw, Rw should be as high as possible. Its value indicates how many dB of sound encountered a window reduces.

Currently, standard windows have an Rwof approximately 30 dB. This is sufficient in quiet surroundings in the countryside or near the city, where the soundproofing of windows does not have to be high.

For very noisy areas, the best sound-insulating glazing can be used - glued laminated glass, which achieves an Rw of up to 51 dB. A window with such a glazing package will achieve an Rw of 45-47 dB. Windows in a house next to a busy road should have an Rw of at least 40 dB for comfort.

Light transmittance Lt

One of the primary functions of any window is to provide an adequate amount of natural light into the room.

The light transmittance value Lt defines the ratio between the amount of sunlight entering a double-glazed unit and the amount of light transmitted through it. It is always given as a percentage. The higher the percentage of transmitted light, the brighter the room will be.

The light transmittance value of an insulating glass unit made of normal float glass can be up to 90%. But if glazing with special properties is used in the glazing package, the Lt value can be quite different. For example, absorptive solar control glass, known as antisol, may be used in the package. This is coloured tinted glass - depending on its thickness and colour, it has the ability to absorb part of the sun's radiation, thus limiting the heating of interiors. However, it also reduces the light transmittance value to between 32 and 72%.

High solar energy transmittance value g (gn)

The gn value describes the ratio of the total energy transmittance of the glass to the incident solar energy (in the range between 300 nanometres and 2500 nanometres).

The transmittance value informs us how much of the solar energy falling on the glass is let into the room. The higher the parameter value, the more solar heat enters the interior.

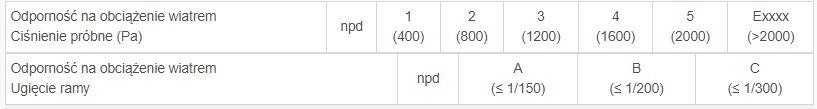

Wind load resistance

Wind load resistance is another important parameter of window joinery, as it informs us about the statics of the window, and thus is directly related to the safety of the window's structure.

This parameter defines up to what wind velocity the window will fulfil its constructional requirements, in other words: what pressure values (caused by wind pressure/suction) your joinery can withstand before it deforms excessively.

The greater the resistance of window's structural elements (mullions, jambs, assemblies of mullions and sashes) to wind pressure and the smaller the fraction of their deflection, the more resistant the structure is. Before a window is placed on the market, according to the requirements of PN-EN 14351-1+A1:2010 its wind load resistance is tested in laboratory conditions. Once the tests have been completed, the tested window structure is marked with the appropriate symbols indicating its wind load resistance class.

The frame deflection is denoted by the letters A, B and C. Class A is ≤ 1/150, B ≤ 1/200 and C ≤ 1/300. Whereas pressure classes are marked with the numbers 1, 2, 3, 4, 5 and Exxxx at pressures exceeding 2000 Pa

source: oknotest.pl

Example of interpretation: if the stated wind load resistance is A3, it means that the most deformed element of the window will collapse below 1/150 of its length without any damage and withstand a pressure not exceeding 1200 Pa. In other words, the most deformable part of the structure deflects permissibly (by a maximum of 1/150 of its length) at a pressure of 1200 Pa, which corresponds to a wind speed of 157.7 km/h

A C5 value, on the other hand, will mean that the window will deform below 1/300 of its length at a pressure of up to 2000 Pa.

Window water penetration resistance class

Water penetration resistance value determines the wind load value during a rainfall at which rainwater will penetrate into the window's structure. The standard PN EN 14351-1:2006 defines as many as 10 classes of water penetration resistance of windows, starting from class 1A to class 9A and class Exxx. ( In the place of xxx the value of pressure is written) Appropriate markings of windows are used depending on the level of pressure to which a window retains complete resistance against rainwater.

A 1A rated window leaks virtually every time, as water already penetrates into the structure at a test pressure of 0 Pa. And the high class 9A means that the window will remain resistant even at 600 Pa, which corresponds to a wind speed of approximately 115 kilometres per hour. Such strong winds, especially in dense urban areas, are virtually non-existent

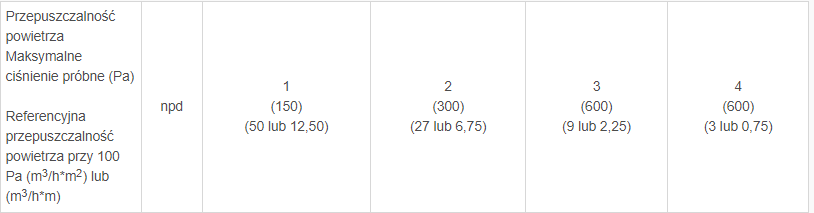

Window air penetration resistance

Another parameter we may encounter when buying a window is an air penetration resistance class. Air penetration resistance - determines how much air will pass through the window joinery

The individual classes are determined by the PN-EN 14351-1+A1:2010 standard indicating that 4 classes of air penetration resistance are determined for windows. The higher the class, the more resistant the window.

In practice, for a class to also meet the standards in force in our country it must be 3 or 4. A window with class 1 or 2 certainly does not meet these requirements,

source okontest.pl

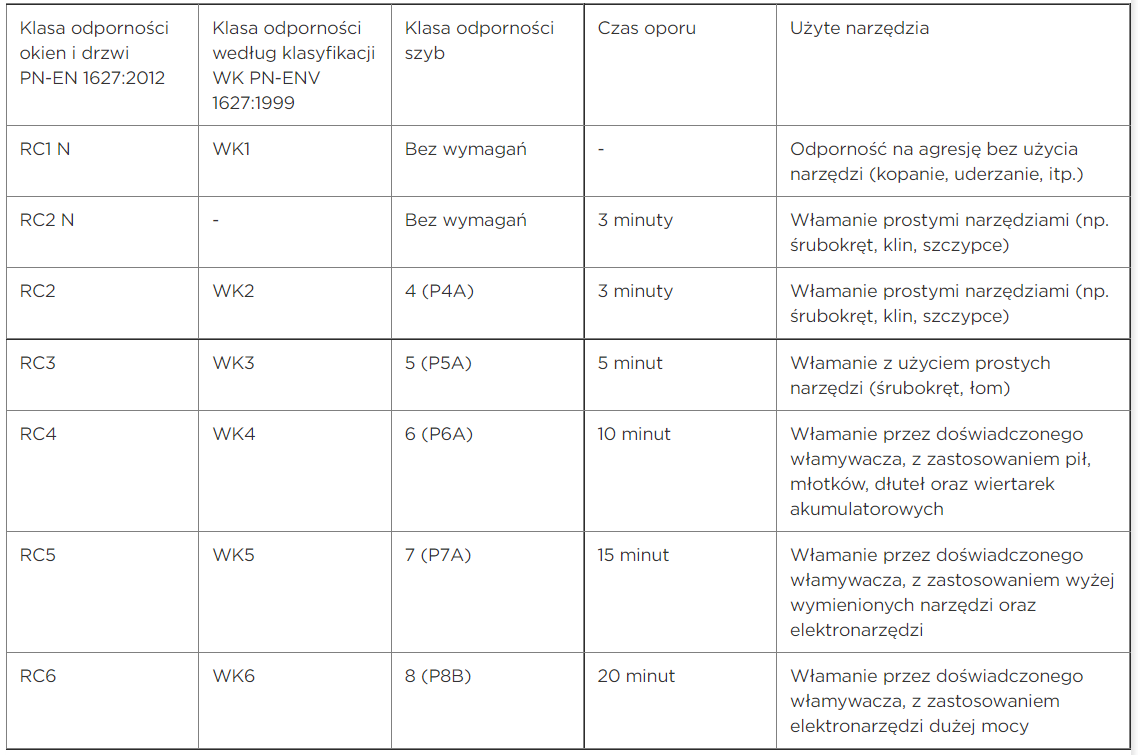

Burglar resistance classes

Balcony windows, terrace windows and large windows on ground-floor level are statistically the weakest link when it comes to the security of our homes. It is these "entrances" that burglars most often choose. How to ensure a peaceful sleep for the residents and secure their property? When choosing anti-burglary fittings, another parameter we should take into account is the RC resistance class of the windows.

Burglary resistance classes inform us about how long and with what tools a window or door can resist a burglary attempt. The table below shows the characteristics of the individual RC resistance classes according to the currently valid PN-EN 1627:2012 standard. The table also includes the WK classification used for many years on the Polish market

source: Winkhaus

Windows with no resistance classes (standard)

As part of standard fittings there is one anti-burglary clip mounted to the lower part of the frame. In case of windows installed above 1 floor or roof windows, standard fittings or basic protection will be sufficient.

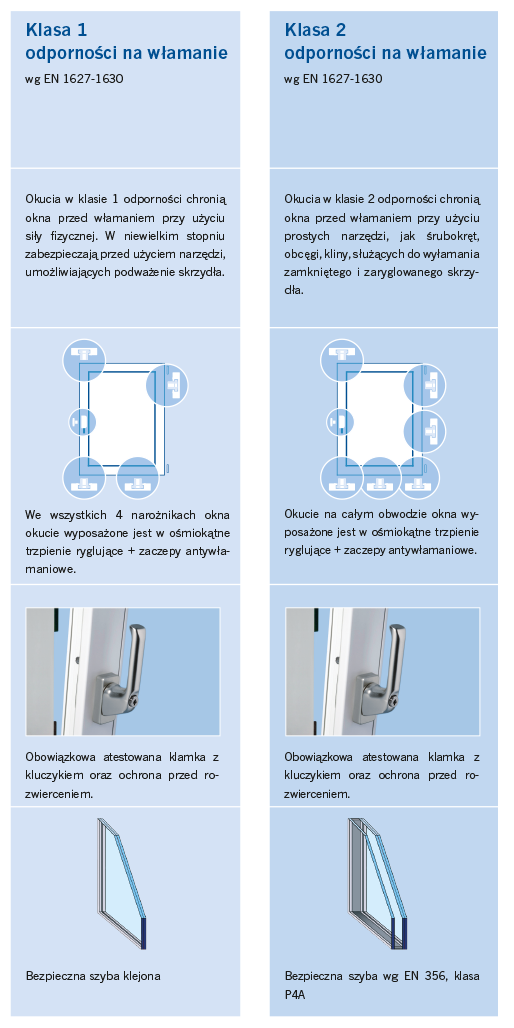

RC1 resistance class windows

RC1 class burglary resistance windows are equipped with a fitting containing 4 security points (one at each corner of the window), an approved handle with a key and an anti-drilling cover for its fitting system. This solution will protect the windows against burglary with physical force.

RC2 class and above

RC2 class windows are equipped with a special anti-burglary glass (P4A), a fitting in which all locks make safety points, an approved handle with a key and an anti-drilling cover for its fitting system. These elements provide superior level of security, which will protect the window against burglary with use of tools.

How do I read the glazing package labelling?

A double-glazed unit is a structure consisting of at least two panes that form an inter-pane chamber containing air or other gases, separated from each other and sealed around its entire circumference by a spacer, sealants and vapour-absorbing substances.

Manufacturers offer single-chamber glazing consisting of two panes of glass and two- and three-chamber glazing consisting of three and four panes of glass (in case of safety glazing and larger number of panes bonded by PVB foil).

Double-glazed unit markings are also often a mystery to buyers, so let's finish with an example of how to read them.

4/16/4 - stands for single chamber double-glazed unit The first value is the outer pane thickness of 4mm, then we have the spacer width of 16mm and finally the inner pane thickness of 4mm.

4/16/4/16/4 – stands for double chamber double-glazed unit 4mm thick outer pane / 16mm wide spacer / 4mm thick middle pane / 16mm wide spacer / 4mm thick inner pane.

You can find more examples of how to read glazing packages markings in our earlier article:

https://www.amokna.net/baza-wiedzy/types-and-parameters-glazing

Polski

Polski English

English Germany

Germany France

France